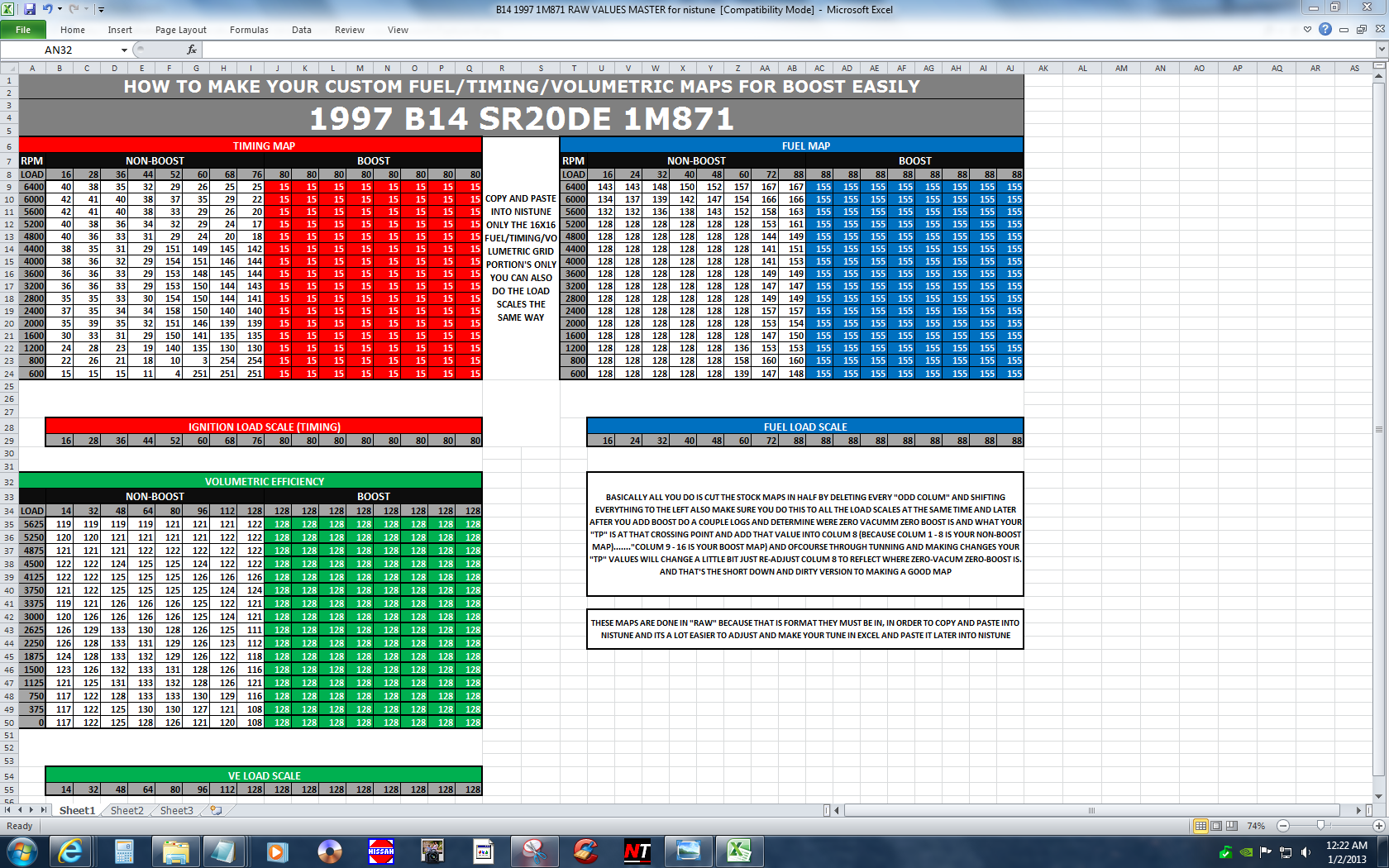

Good stuff. I've been considering the different ways of setting up the TP scale too. At first I was simply increasing the values in the last 4 columns to stop it from "running off the end". This works but it's not ideal.

Now I regularly re-scale by applying a similar factor across the board. I normally take note of what value TP goes to at max boost and use this as the TP value for the last column, then scale back from here.

What I'm wondering is this: I see it as most important that the engine runs ideal timing figures at each boost level. But what I've found is that usually I'll tune for say 16psi max, then if I turn boost back to 12 or 14psi there isn't much difference in which cells are accessed. Result being that at 12psi it's running similar timing figures to what it's running at 16psi. Which is crap cos you can run lots more timing at 12psi!

The bit I don't care about that much is the off boost (usually closed loop) stuff. So why not scale it so that this low load stuff only takes up 1/2 (or less) of the load scale and the on-boost stuff can then work across 6 to 8 columns. Giving lots more resolution for tuning at different boost levels.

I haven't tried this yet because it's obviously gonna take quite a bit of work to get the figures in the maps correct. But I'd be interested to hear what others think.

PL